AENG 252 :: Lecture 03 :: GROUNDNUT DECORTICATOR-HAND OPERATED AND POWER OPERATED DECORTICATORS, CARE AND MAINTENANCE

![]()

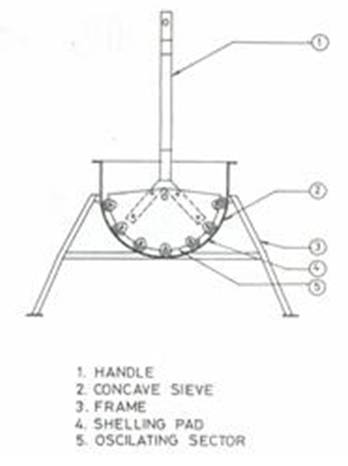

Groundnut decorticator: Manually operated

Hand operated groundnut decorticator consists of curved ‘L’ angle frame and four legs. A perforated sieve in a semi circular shape is provided. Seven cast iron peg assemblies are fitted in an oscillating sector. The groundnut pods are shelled between the oscillating sector and the perforated concave sieve. The kernels and husk are collected at the bottom of the unit. The clearance between the concave and oscillating sector is adjustable to decorticate pods of different varieties of groundnut. The sieve is also replaceable according to the variety of groundnut pods.

Fig. Groundnut decorticator: Manually operated

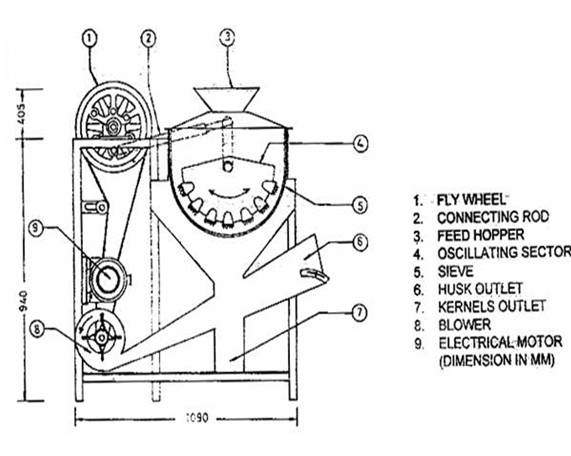

Groundnut decorticator: Power operated

The unit consists of a hopper, double crank lever mechanism, an oscillating sector with sieve bottom and blower assembly, all fixed on a frame. A number of cast iron peg assemblies are fitted ion the oscillating sector unit. The groundnut pods are shelled between an oscillating sector and the fixed perforated concave screen. The decorticated shells and kernels fall down through the perforated concave sieve. The blower helps to separate the kernels from the husk and the kernel are collected through the spout at the bottom. The shells are thrown away from the machine.

Fig. Groundnut decorticator: Power operated

| Download this lecture as PDF here |

![]()